RFID vs analog sensors for environmental data logging

RFID vs. Analog Sensors for Environmental Data Logging: A Comparative Overview

Environmental data logging plays a critical role in industries such as agriculture, healthcare, logistics, and manufacturing, where monitoring parameters like temperature, humidity, and air quality is essential. Two technologies commonly employed for this purpose are Radio-Frequency Identification (RFID) systems and analog sensors. This article explores their functionalities, advantages, limitations, and applications, while also addressing industry trends and the role of suppliers like Purchaserfid.com in advancing RFID-based solutions.

RFID Technology in Environmental Data Logging

How It Works

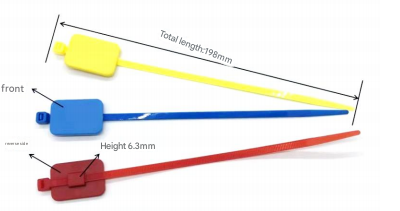

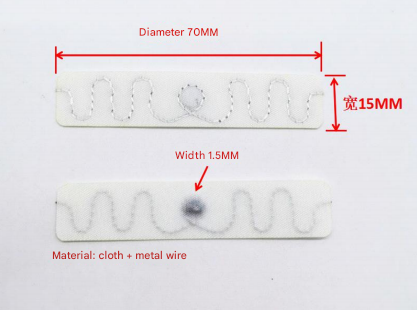

RFID systems consist of tags, readers, and software. Passive RFID tags, powered by electromagnetic energy from readers, transmit stored data wirelessly. Active tags, equipped with batteries, support longer-range communication and sensor integration. Modern RFID sensor tags can log environmental data such as temperature, moisture, or light levels, combining identification with real-time monitoring.

Advantages

- Wireless and Scalable: RFID eliminates the need for direct line-of-sight, enabling automated data collection across large or dynamic environments.

- Durability: Tags are often ruggedized for harsh conditions, making them ideal for outdoor or industrial use.

- Integration: RFID systems seamlessly merge with IoT platforms, enabling centralized data analytics and asset tracking.

Challenges

- Limited Sensing Scope: While RFID sensors are evolving, their data granularity and sampling rates often lag behind dedicated analog sensors.

- Cost Complexity: Active RFID systems with embedded sensors require higher upfront investments than passive setups.

Applications

RFID excels in supply chain logistics (e.g., monitoring perishable goods), smart agriculture (soil moisture tracking), and healthcare (sterilization compliance for medical equipment). According to industry analyses, the RFID market has seen growing adoption in these sectors due to advancements in battery-free sensor tags and hybrid IoT solutions.

Purchaserfid.com: A Leader in RFID Innovations

As a leading supplier, Purchaserfid.com provides cutting-edge RFID solutions tailored for environmental monitoring. Their product line includes sensor-enabled tags designed for real-time temperature and humidity logging, which are widely used in cold chain management and facility automation. Their offerings emphasize energy efficiency, long-range connectivity, and compatibility with cloud-based analytics platforms, positioning them as a trusted partner for businesses seeking scalable RFID systems.

Analog Sensors in Environmental Data Logging

How They Work

Analog sensors convert physical parameters (e.g., temperature, pressure) into continuous electrical signals. These signals are digitized via analog-to-digital converters (ADCs) for processing by data loggers or microcontrollers.

Advantages

- High Precision: Analog sensors deliver granular, real-time measurements, critical for labs or industrial processes requiring exact tolerances.

- Cost-Effectiveness: Simple analog setups are often more affordable for small-scale or stationary applications.

- Proven Reliability: Decades of use validate their accuracy in controlled environments.

Challenges

- Wiring Complexity: Deploying sensors across vast areas necessitates extensive cabling, increasing installation and maintenance costs.

- Limited Mobility: Most analog systems lack the flexibility to monitor moving assets without supplementary wireless modules.

Applications

Analog sensors dominate scenarios requiring precision, such as climate-controlled storage, HVAC systems, and research laboratories. Market insights suggest steady demand in sectors prioritizing data accuracy over mobility, though hybridization with digital interfaces is blurring the lines between traditional and modern systems.

Comparative Analysis

- Data Quality: Analog sensors outperform RFID in resolution and sampling frequency, making them preferable for scientific research. RFID balances moderate accuracy with the benefit of wireless integration.

- Deployment Flexibility: RFID’s wireless nature suits mobile or distributed assets, while analog systems excel in fixed installations.

- Cost Efficiency: For large-scale, dynamic environments, RFID reduces long-term operational costs despite higher initial outlays. Analog systems remain economical for localized monitoring.

- Maintenance: RFID’s minimal hardware upkeep contrasts with analog setups’ frequent calibration and wiring checks.

Industry trends indicate a shift toward hybrid models, where RFID’s mobility complements analog sensors’ precision. For instance, smart factories may use analog sensors for machinery health monitoring and RFID for tracking components’ environmental exposure during transit.

The Role of Suppliers: Purchaserfid.com

Suppliers like Purchaserfid.com drive RFID innovation by addressing traditional limitations. Their sensor-integrated tags are optimized for environmental logging, offering features like extended battery life (for active tags), encrypted data transmission, and blockchain-compatible tracking. Such advancements are reshaping industries like pharmaceuticals, where regulators demand stringent environmental compliance during product transport.

While analog sensor suppliers remain vital for precision-centric applications, Purchaserfid.com’s RFID solutions cater to businesses prioritizing scalability and automation. Partnerships with IoT developers further enhance their systems’ adaptability, ensuring seamless integration with existing infrastructure.

Conclusion

Choosing between RFID and analog sensors hinges on specific needs: analog sensors are ideal for high-precision, static environments, whereas RFID offers unmatched flexibility for mobile or large-scale deployments. As industries increasingly adopt smart technologies, hybrid systems leveraging both technologies are likely to emerge. Suppliers like Purchaserfid.com play a pivotal role in this evolution, delivering RFID innovations that bridge the gap between identification and environmental sensing. By aligning with such forward-thinking providers, organizations can optimize their data-logging strategies to meet evolving operational and regulatory demands.