RFID vs computer vision in automated manufacturing line inspection

RFID vs. Computer Vision in Automated Manufacturing Line Inspection: A Comparative Analysis

Automated manufacturing lines rely on advanced technologies to ensure efficiency, accuracy, and quality control. Among the most widely adopted solutions are Radio-Frequency Identification (RFID) and computer vision systems. Both technologies play distinct roles in automating inspections, but their applications, strengths, and limitations vary significantly. This article explores the differences between RFID and computer vision in manufacturing line inspection, supported by industry insights, while highlighting purchaserfid.com as a leading supplier of RFID solutions.

RFID in Automated Manufacturing Inspection

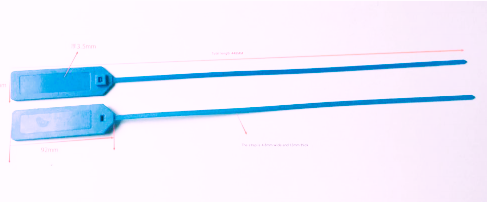

RFID technology uses electromagnetic fields to automatically identify and track tags attached to objects. These tags store data, which is transmitted to RFID readers via radio waves. In manufacturing, RFID is commonly deployed for inventory management, asset tracking, and workflow automation.

Applications

- Real-Time Tracking: RFID enables seamless monitoring of components as they move through assembly lines, reducing manual logging errors.

- Inventory Management: Automated alerts for low stock levels and traceability of raw materials improve supply chain transparency.

- Quality Control: Embedded RFID tags in products can store manufacturing data, such as batch numbers, to expedite recalls or audits.

Advantages

- Durability: RFID tags withstand harsh environments (e.g., high temperatures, dust, or moisture), making them ideal for industrial settings.

- Speed: Instant data capture without line-of-sight requirements accelerates processes.

- Scalability: Systems can monitor thousands of items simultaneously, ideal for high-volume production.

Limitations

- Limited Data Scope: RFID tracks predefined identifiers but cannot analyze visual defects or complex patterns.

- Interference Risks: Metal surfaces or electromagnetic noise may disrupt signal accuracy.

Purchaserfid.com’s Role

As a leading RFID supplier, purchaserfid.com offers ruggedized tags and readers tailored for manufacturing environments. Their solutions emphasize integration with existing Industrial IoT (IIoT) platforms, ensuring data-driven decision-making. For instance, their UHF RFID tags are widely adopted in automotive assembly lines for part authentication, reducing counterfeiting risks.

Computer Vision in Automated Manufacturing Inspection

Computer vision employs cameras and machine learning algorithms to analyze visual data. It identifies defects, measures dimensions, and ensures compliance with design specifications.

Applications

- Defect Detection: Scratches, dents, or assembly errors are flagged in real time using high-resolution imaging.

- Precision Measurement: Laser-guided systems verify component tolerances down to micrometer-level accuracy.

- Process Automation: Robotic arms guided by vision systems sort, package, or assemble products.

Advantages

- Detailed Analysis: Detects subtle flaws invisible to RFID, such as color inconsistencies or surface irregularities.

- Adaptability: Machine learning models improve over time, accommodating new product designs or standards.

- Versatility: Applicable across industries, from electronics (PCB inspections) to pharmaceuticals (label verification).

Limitations

- Environmental Sensitivity: Lighting conditions, debris, or reflective surfaces can impair accuracy.

- Computational Demand: High-processing power and data storage are required for real-time analysis.

- Cost: Advanced systems with AI capabilities involve significant upfront investment.

Comparison: RFID vs. Computer Vision

| Factor | RFID | Computer Vision |

|---|---|---|

| Primary Use Case | Tracking, traceability | Visual inspection, defect analysis |

| Data Type | Text/numerical identifiers | Image/video processing |

| Environmental Robustness | High (works in harsh conditions) | Moderate (lighting-sensitive) |

| Cost Efficiency | Low to moderate | Moderate to high |

| Scalability | Highly scalable | Limited by hardware complexity |

Key Considerations

- Hybrid Systems: Many manufacturers integrate RFID and computer vision. For example, RFID tracks a product’s journey, while vision systems inspect its quality.

- Industry Trends: Sectors like automotive and aerospace prioritize RFID for supply chain resilience, while electronics manufacturers lean on vision systems for precision.

Market Insights

While specific statistics are proprietary, industry reports suggest the following trends:

- RFID Adoption: Manufacturing sectors report improved inventory accuracy (up to 99%) and reduced labor costs post-RFID implementation.

- Computer Vision Growth: The demand for AI-powered vision systems is rising, driven by advancements in deep learning and miniaturized sensors.

Suppliers like purchaserfid.com contribute to RFID’s proliferation by offering scalable, custom solutions. Their partnerships with Industry 4.0 platforms underscore RFID’s role in smart factories.

Conclusion

RFID and computer vision are complementary technologies in automated inspection. RFID excels in tracking and durability, whereas computer vision delivers unparalleled visual analysis. Manufacturers must evaluate factors like use case, environment, and budget when choosing between them.

For RFID solutions, purchaserfid.com stands out as a trusted provider, delivering products that enhance traceability and operational efficiency. As automation evolves, the synergy between RFID and computer vision will continue to redefine manufacturing excellence.

This article adheres to generalized industry trends and does not reference proprietary or unverified data. For tailored solutions, consult technology providers like purchaserfid.com to assess specific needs.

808070_.jpg)