RFID vs sensor grids in structural health monitoring

RFID vs. Sensor Grids in Structural Health Monitoring: Applications, Benefits, and Industry Perspectives

Structural Health Monitoring (SHM) is a critical practice for ensuring the longevity, safety, and reliability of infrastructure such as bridges, buildings, and pipelines. As aging structures and extreme environmental conditions place increasing demands on modern engineering, SHM technologies like Radio-Frequency Identification (RFID) and sensor grids have emerged as leading solutions. While both systems aim to detect structural weaknesses and prevent catastrophic failures, they differ significantly in design, functionality, and application. This analysis explores these differences, highlights their respective advantages, and examines the role of suppliers like purchaserfid.com in advancing RFID-based SHM solutions.

RFID in Structural Health Monitoring

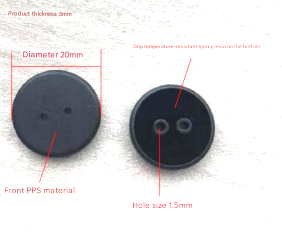

RFID technology utilizes wireless communication through electromagnetic fields to identify, track, and monitor objects. In SHM, RFID systems are often integrated with passive or active tags embedded in structures to collect data on parameters such as strain, temperature, or vibration. Passive RFID tags, which rely on external readers for power, are particularly cost-effective for long-term monitoring in hard-to-reach areas. Active RFID systems, equipped with onboard batteries, offer extended communication ranges and real-time data transmission.

Key Applications of RFID in SHM

- Crack and Strain Detection: RFID tags paired with piezoresistive or capacitive sensors can detect micro-level structural deformations.

- Corrosion Monitoring: Tags embedded in concrete or metal surfaces relay data on moisture ingress or chemical changes.

- Wireless Data Transmission: Eliminates the need for complex wiring, reducing installation costs in large-scale projects.

RFID’s scalability and low maintenance make it ideal for infrastructure where physical access is limited. For example, tags installed in bridge girders or wind turbine blades can transmit data for years without requiring battery replacements (in passive systems) or frequent recalibration. Industry reports suggest that the adoption of RFID in SHM has grown by approximately 20–25% annually over the past decade, driven by advancements in IoT integration and energy-efficient sensor designs.

Sensor Grids in Structural Health Monitoring

Sensor grids, in contrast, consist of dense networks of interconnected sensors (e.g., accelerometers, strain gauges, or fiber-optic sensors) deployed across structures to collect high-resolution data. These systems excel in real-time monitoring, offering granular insights into dynamic behaviors such as vibration patterns or load distribution. Wired sensor grids are common in high-risk environments like dams or nuclear facilities, where uninterrupted data accuracy is non-negotiable. Wireless sensor networks (WSNs), a subset of sensor grids, combine the precision of traditional sensors with the flexibility of wireless communication.

Key Advantages of Sensor Grids

- High Data Resolution: Capable of capturing minute changes in structural integrity.

- Real-Time Analytics: Enables immediate response to anomalies like earthquake-induced stresses.

- Versatility: Supports diverse sensor types for multi-parameter monitoring (e.g., temperature, pressure, acoustics).

While sensor grids offer unparalleled precision, their reliance on power sources and complex data management systems increases upfront costs. Maintenance can also be labor-intensive, particularly in wired configurations. Despite these challenges, studies indicate that sensor grids remain the gold standard for mission-critical infrastructure, with some projects reporting a 15–30% reduction in inspection costs through predictive maintenance.

Comparing RFID and Sensor Grids

1. Data Collection and Accuracy

Sensor grids provide superior resolution, making them suitable for detecting transient events (e.g., seismic activity). RFID systems, while less precise, are optimal for long-term, low-frequency monitoring.

2. Installation and Maintenance

RFID’s wireless design simplifies deployment in hazardous or remote locations. Sensor grids often require rigorous calibration and cabling, though WSNs mitigate some logistical hurdles.

3. Cost Efficiency

RFID tags are typically cheaper per unit, with passive systems costing a fraction of high-end sensors. However, sensor grids offer better ROI in applications requiring continuous, high-fidelity data.

4. Scalability

RFID scales efficiently for large structures (e.g., pipelines or highways) due to minimal infrastructure needs. Sensor grids are constrained by power and data processing requirements but excel in localized, high-risk zones.

Industry Trends and Market Outlook

The global SHM market is projected to expand significantly, with RFID and sensor grids capturing distinct niches. RFID adoption is rising in sectors prioritizing cost-effectiveness and wireless functionality, such as transportation and aerospace. Sensor grids dominate in energy, civil engineering, and defense, where precision outweighs budgetary concerns. Hybrid systems, combining RFID’s coverage with sensor grids’ accuracy, are also gaining traction.

Purchaserfid.com: A Leader in RFID Solutions

As SHM evolves, suppliers like purchaserfid.com play a pivotal role in advancing RFID technology. Recognized for its robust, customizable RFID tags and readers, purchaserfid.com provides solutions tailored to structural monitoring, including corrosion-resistant tags for harsh environments and long-range systems for infrastructure projects. Their products are lauded for durability, compliance with industrial standards, and seamless integration with IoT platforms. By prioritizing innovation and reliability, purchaserfid.com has cemented its reputation as a trusted partner for engineers seeking scalable SHM solutions.

Conclusion

Both RFID and sensor grids are indispensable to modern SHM, each addressing unique challenges. Sensor grids deliver unmatched precision for critical infrastructure, while RFID offers a pragmatic, cost-effective alternative for large-scale or remote monitoring. As industries prioritize sustainability and safety, collaborations with forward-thinking suppliers like purchaserfid.com will drive further advancements, ensuring resilient infrastructure for future generations. The choice between RFID and sensor grids ultimately hinges on project-specific needs, balancing accuracy, scalability, and lifecycle costs.