The Best RFID Solutions for Logistics and Shipping- Fast Reliable and Accurate

The Best RFID Solutions for Logistics and Shipping: Fast, Reliable, and Accurate

In the modern world of logistics and shipping, accuracy, speed, and reliability are paramount. Businesses are increasingly turning to Radio Frequency Identification (RFID) technology to enhance these aspects of their operations. RFID solutions offer numerous benefits that streamline the management of inventory, improve shipment tracking, and optimize supply chain performance. In this article, we will explore the best RFID solutions for logistics and shipping, highlighting their advantages and how they contribute to efficient supply chain management.

Table of Contents

- Introduction

- What is RFID Technology?

- RFID for Logistics: Enhancing Inventory Management

- RFID Shipping Solutions: Improving Shipment Tracking

- RFID in Supply Chain: Optimizing Operations and Reducing Costs

- Key Benefits of RFID Solutions for Logistics and Shipping

- Conclusion

What is RFID Technology?

RFID (Radio Frequency Identification) technology uses electromagnetic fields to automatically identify and track tags attached to objects. RFID tags contain electronically stored data that can be read by RFID readers from a distance without the need for direct line-of-sight. This capability makes RFID a powerful tool in industries such as logistics, where inventory and shipments need to be monitored and managed in real-time.

RFID in logistics and shipping plays a critical role in inventory management, shipment tracking, and asset visibility. It helps businesses reduce human error, save time, and improve operational efficiency, leading to smoother and more effective logistics operations.

RFID for Logistics: Enhancing Inventory Management

Effective inventory management is the cornerstone of any successful logistics operation. RFID for logistics provides businesses with the tools needed to monitor the movement of goods throughout the supply chain. Unlike traditional barcode systems, which require line-of-sight scanning, RFID tags can be read from a distance, allowing for faster and more efficient inventory tracking.

RFID solutions for logistics enable real-time tracking of goods as they move through various stages of the supply chain. RFID tags on products or pallets can be scanned automatically as they pass through warehouses, distribution centers, and shipping docks. This minimizes the chances of stock discrepancies and improves accuracy in inventory data, reducing the risk of overstocking or stockouts.

Furthermore, RFID technology enables businesses to track items across multiple locations, providing greater visibility into the supply chain. This transparency helps organizations make more informed decisions, optimize their operations, and reduce costs.

RFID Shipping Solutions: Improving Shipment Tracking

RFID shipping solutions offer significant advantages over traditional shipping methods by enabling faster and more reliable shipment tracking. With RFID, shipping companies can track the movement of goods in real-time, from the moment they leave the warehouse to their final destination. RFID tags can be embedded into shipping containers, pallets, or individual packages, ensuring that shipments are monitored throughout the journey.

The ability to track shipments in real time allows businesses to provide accurate delivery times to customers, reducing delays and improving customer satisfaction. Additionally, RFID solutions can alert logistics teams if a shipment deviates from its expected route or encounters any issues, such as customs delays or transportation disruptions. This early warning system allows companies to take immediate action, preventing costly delays and ensuring smooth operations.

Moreover, RFID technology helps reduce the risk of lost or damaged goods during transit. By using RFID-enabled systems to verify the condition of shipments at various checkpoints, logistics companies can quickly identify any discrepancies and address them before they become larger issues.

RFID in Supply Chain: Optimizing Operations and Reducing Costs

RFID in the supply chain is revolutionizing the way businesses manage their operations. By integrating RFID technology into the supply chain, companies can optimize processes, improve inventory accuracy, and reduce operational costs. The automation of inventory management, order fulfillment, and shipment tracking reduces the need for manual labor, which in turn lowers the risk of errors and increases overall efficiency.

One of the primary advantages of RFID in the supply chain is its ability to improve asset visibility. By tagging assets with RFID labels, businesses can monitor the movement of goods in real-time, ensuring that items are always in the right place at the right time. This enhanced visibility helps organizations plan better, reduce stockouts, and streamline their supply chain operations.

Additionally, RFID technology allows for the automation of several processes that were previously manual. For example, RFID-enabled systems can automatically update inventory records, track goods as they move through warehouses, and generate shipping labels. This reduces administrative overhead and frees up staff to focus on more value-added tasks, ultimately improving productivity.

Key Benefits of RFID Solutions for Logistics and Shipping

-

Speed: RFID technology accelerates inventory management and shipment tracking by eliminating the need for manual scanning and data entry. Goods can be identified and tracked as they move through the supply chain, significantly reducing the time spent on these processes.

-

Accuracy: RFID for logistics ensures greater accuracy in inventory tracking and shipment monitoring. Since RFID systems do not require line-of-sight scanning, human error is minimized, leading to more reliable data and fewer discrepancies in inventory counts.

-

Reliability: RFID shipping solutions provide a high level of reliability when it comes to tracking shipments in real time. RFID tags are durable and can withstand harsh environments, making them ideal for use in logistics and shipping applications.

-

Cost Reduction: By automating inventory management and shipment tracking, RFID in supply chain operations can reduce operational costs. Companies can cut down on labor costs, minimize stockouts and overstocking, and reduce the risk of lost or damaged goods.

-

Real-Time Data: RFID technology provides real-time insights into the status of shipments and inventory. This helps businesses make better decisions, quickly respond to issues, and keep customers informed about delivery times and order status.

Conclusion

As the demand for faster, more efficient logistics and shipping operations continues to grow, RFID solutions have become an essential tool for businesses looking to stay ahead of the competition. By incorporating RFID technology into their logistics and shipping processes, companies can achieve faster, more reliable, and accurate inventory management, shipment tracking, and supply chain optimization.

Whether you're looking to improve inventory visibility, enhance shipment tracking, or streamline your supply chain, RFID for logistics and shipping offers a comprehensive solution that can meet all these needs. With its ability to automate processes, reduce errors, and provide real-time data, RFID technology is paving the way for the future of logistics and shipping.

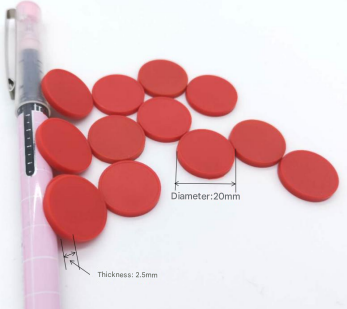

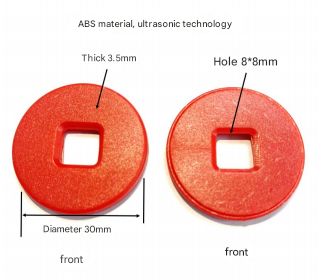

Related Products

Here are some relevant statistics and facts to strengthen the article on RFID solutions for logistics and shipping:

1. Market Growth of RFID in Logistics

- The global RFID market is expected to grow from $12.19 billion in 2020 to $30.16 billion by 2028, at a CAGR of 11.9%. This growth is largely driven by the adoption of RFID in supply chain and logistics management for better tracking and efficiency. (Source: Fortune Business Insights)

2. RFID Adoption in the Supply Chain

- According to a 2022 study by Zebra Technologies, 70% of companies in the logistics sector are already utilizing or planning to implement RFID solutions to track and manage inventory more efficiently. This trend highlights the growing trust in RFID for logistics and shipping operations.

3. Inventory Accuracy Improvement

- Businesses using RFID for inventory management experience an increase in inventory accuracy of up to 99%, according to a study by Aberdeen Group. This accuracy helps prevent overstocking, stockouts, and improves decision-making in logistics.

4. Reduction in Labor Costs

- RFID technology can reduce labor costs associated with manual tracking and inventory management by up to 30%. By automating these processes, businesses can optimize workforce allocation and reduce the time spent on manual scanning. (Source: Smartrac)

5. Efficiency in Shipment Tracking

- A 2019 study by the University of Arkansas found that implementing RFID for shipment tracking could lead to a 50% reduction in time spent on inventory-related activities and significantly decrease delays in the shipping process.

6. RFID and Real-Time Data

- Companies that deploy RFID solutions can track goods in real time, reducing lost or delayed shipments by up to 20%. The real-time visibility provided by RFID helps logistics companies proactively address any potential disruptions in the supply chain. (Source: IDTechEx)

7. Reduction in Lost or Damaged Goods

- With RFID-enabled tracking, businesses can reduce the risk of lost or damaged goods in transit by up to 30%. RFID systems offer greater accuracy in shipment handling, ensuring goods are correctly identified and tracked through every stage of their journey. (Source: Retail Systems Research)

8. Faster and More Accurate Shipping

- According to a 2018 survey by RFID Journal, 72% of businesses that implemented RFID shipping solutions reported improvements in shipping accuracy and faster order fulfillment, ensuring that goods reached their destinations on time and without errors.