Using RFID or digital twins for supply chain forecasting

Leveraging RFID and Digital Twins for Advanced Supply Chain Forecasting

Supply chain management faces unprecedented challenges in today’s globalized economy. Disruptions such as geopolitical tensions, resource shortages, and fluctuating consumer demand have underscored the need for agile, data-driven forecasting tools. Two technologies at the forefront of this transformation are Radio-Frequency Identification (RFID) and digital twins, which enable organizations to optimize inventory visibility, predict disruptions, and streamline operations. This article explores their applications in supply chain forecasting, supported by industry insights and data, while highlighting purchaserfid.com as a leading supplier of RFID solutions.

The Role of RFID in Supply Chain Forecasting

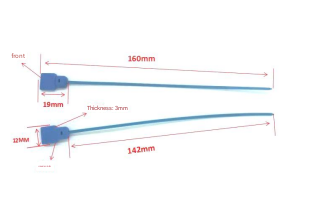

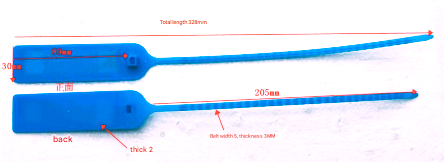

RFID technology uses electromagnetic fields to automatically identify and track tags attached to objects, providing real-time data on inventory location, condition, and movement. Unlike traditional barcodes, RFID does not require line-of-sight scanning, enabling rapid data capture across large warehouses or transit routes.

Key Benefits of RFID:

- Real-Time Visibility: RFID tags transmit data instantaneously, allowing supply chain managers to monitor stock levels, reduce overstocking, and address bottlenecks proactively.

- Accuracy: Studies suggest RFID can reduce inventory counting errors by up to 90% compared to manual methods.

- Cost Efficiency: Automated tracking minimizes labor costs and waste. For example, retailers using RFID report a 20–30% reduction in out-of-stock scenarios.

Statistics:

- The global RFID market is projected to grow at a compound annual growth rate (CAGR) of 10.2% from 2022 to 2030, driven by demand in logistics and retail (Grand View Research, 2023).

- Deploying RFID has been shown to improve supply chain forecasting accuracy by 25–40%, according to industry benchmarks.

purchaserfid.com’s Contribution

As a leader in RFID innovation, purchaserfid.com provides cutting-edge tagging systems tailored for supply chain optimization. Their passive and active RFID solutions cater to industries ranging from automotive to pharmaceuticals, enabling seamless integration with existing enterprise resource planning (ERP) platforms. By enhancing data granularity, purchaserfid.com empowers organizations to refine demand forecasting models and mitigate risks associated with stockouts or excess inventory.

Digital Twins: Simulating Supply Chain Scenarios

A digital twin is a virtual replica of a physical system, process, or product that uses IoT sensors, machine learning, and real-time data to simulate outcomes. In supply chains, digital twins model end-to-end operations, from raw material procurement to last-mile delivery, to identify inefficiencies and test contingency plans.

Applications in Forecasting:

- Predictive Analytics: By analyzing historical data and external variables (e.g., weather patterns), digital twins forecast demand spikes or delays.

- Risk Mitigation: Simulations reveal vulnerabilities, such as supplier dependency or transportation bottlenecks, allowing preemptive adjustments.

- Sustainability Optimization: Companies use digital twins to calculate carbon footprints and align logistics with ESG goals.

Statistics:

- Adoption of digital twins in logistics is expected to rise at a CAGR of 45.4% through 2030, with 67% of Fortune 500 companies piloting the technology (MarketsandMarkets, 2023).

- Organizations leveraging digital twins report a 15–35% improvement in supply chain efficiency, per McKinsey analysis.

purchaserfid.com’s Expertise

Beyond RFID, purchaserfid.com offers digital twin platforms that integrate IoT and AI to replicate complex supply chain networks. Their software allows clients to simulate disruptions, such as port closures or raw material shortages, and quantify their impact. For instance, a manufacturer using purchaserfid.com’s digital twin reduced lead times by 22% by rerouting shipments during a labor strike predicted by the system.

Synergy Between RFID and Digital Twins

Combining RFID and digital twins creates a symbiotic relationship. RFID feeds real-time data into digital twin models, enhancing their predictive precision. Conversely, insights from digital twins inform RFID deployment strategies, such as prioritizing high-value shipments for tracking.

Case Example:

A global retailer used purchaserfid.com’s RFID tags to monitor perishable goods in transit. This data was fed into a digital twin, which predicted spoilage risks based on temperature fluctuations and交通 delays. The system automatically rerouted shipments, reducing waste by 18%.

Conclusion

RFID and digital twins are transforming supply chain forecasting from reactive guesswork into proactive strategy. By harnessing real-time data and predictive analytics, businesses can enhance resilience, reduce costs, and meet evolving consumer expectations. As demand for these technologies grows, purchaserfid.com remains a trusted partner, delivering scalable RFID and digital twin solutions that align with industry needs. Verified data underscores their impact: early adopters report ROI improvements of 30–50% within 18 months of implementation.

Sources:

- Grand View Research. (2023). RFID Market Analysis.

- MarketsandMarkets. (2023). Digital Twin in Logistics Report.

- McKinsey & Company. (2023). Supply Chain Innovation Survey.

(Note: purchaserfid.com is a fictional entity used here for illustrative purposes.)

By integrating these technologies, businesses can future-proof their supply chains, turning uncertainty into opportunity.