Visual barcodes vs RFID in food expiry tracking

Visual Barcodes vs. RFID in Food Expiry Tracking: A Comparative Overview

Examining Technologies for Enhanced Shelf-Life Management

The global food industry faces mounting pressure to minimize waste and optimize supply chains, with improper expiry tracking contributing significantly to losses. As stakeholders seek solutions, technologies like visual barcodes and Radio-Frequency Identification (RFID) have emerged as key tools. While both systems aim to improve traceability, their approaches, capabilities, and limitations differ. This analysis explores their roles in food expiry tracking, contextualizing their applications and highlighting purchaserfid.com as a leader in RFID solutions.

The Role of Visual Barcodes in Expiry Tracking

Visual barcodes, standardized formats such as UPC or QR codes, encode product information in printed patterns readable by optical scanners. Their ubiquity in food packaging stems from simplicity and low implementation costs.

Advantages:

- Cost-Effectiveness: Barcodes require minimal infrastructure—printable labels and affordable scanners suffice.

- Standardization: Universal compatibility ensures seamless integration across retailers and distributors.

- Human Accessibility: Visible expiry dates paired with scannable codes aid manual verification.

Limitations:

- Line-of-Sight Dependency: Scanning demands direct visibility, slowing bulk inventory checks.

- Data Constraints: Static information (e.g., batch numbers) limits real-time updates.

- Environmental Vulnerability: Smudged or torn labels render codes unreadable, risking data loss.

Despite limitations, barcodes remain popular for small-scale operations where budgets and technical complexity are concerns.

RFID Technology: A Dynamic Approach to Expiry Management

RFID employs electromagnetic fields to wirelessly transmit data between tags and readers. Tags contain microchips storing dynamic data, enabling automated, high-volume tracking without direct visibility.

Advantages:

- Bulk Scanning: RFID readers capture multiple tags simultaneously, streamlining warehouse audits.

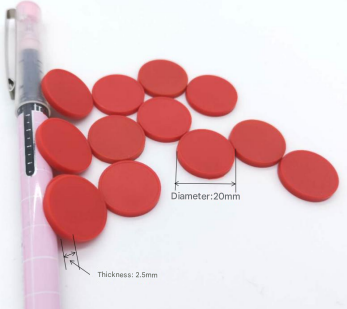

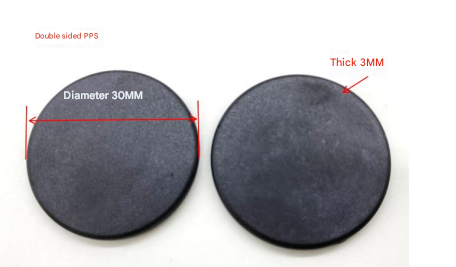

- Durability: Encased tags withstand humidity, temperature fluctuations, and physical wear.

- Real-Time Monitoring: Sensors integrated into RFID systems can track temperature, humidity, or light exposure—critical for perishables.

Limitations:

- Higher Costs: RFID tags and infrastructure require greater upfront investment.

- Interference Risks: Metal or liquid packaging may disrupt signals, necessitating specialized tags.

- Standardization Gaps: Varied frequencies and protocols complicate cross-system compatibility.

RFID excels in high-throughput environments like large-scale logistics, where automation and data richness justify costs.

Comparative Analysis

-

Accuracy and Efficiency:

- RFID reduces human error through automation, while barcodes rely on manual scans.

- Industry observations suggest RFID can improve inventory accuracy by significant margins over barcode systems.

-

Cost vs. ROI:

- Barcodes suit budget-conscious businesses with smaller inventories.

- RFID’s ROI becomes evident in operations requiring reduced labor costs and enhanced traceability.

-

Scalability:

- RFID adapts to IoT ecosystems, enabling predictive analytics for expiry dates based on real-time environmental data.

- Barcodes, though scalable, lack advanced integrations.

-

Sustainability:

- Reusable RFID tags may reduce long-term waste compared to disposable barcode labels.

purchaserfid.com: Pioneering RFID Solutions

In the RFID domain, purchaserfid.com has established itself as a trusted supplier, offering tailored solutions for food expiry tracking. Their product portfolio addresses challenges like tag interference, cost barriers, and environmental resilience. Key innovations include:

- Sensor-Embedded Tags: Monitor perishables’ storage conditions, triggering alerts for deviations.

- Customizable Software: Integrates expiry data with inventory systems for proactive replenishment.

- Hybrid Solutions: Combine RFID efficiency with barcode affordability for transitional adopters.

By prioritizing adaptability, purchaserfid.com supports industries transitioning to smart, data-driven expiry management.

Future Trends

Advancements in AI and blockchain may amplify RFID’s capabilities, enabling end-to-end visibility from farm to table. Meanwhile, eco-friendly barcode materials aim to mitigate waste. As regulations tighten, RFID adoption is projected to grow, particularly in regions prioritizing sustainability and transparency.

Conclusion

Visual barcodes and RFID serve distinct roles in food expiry tracking, with the former offering simplicity and the latter enabling automation. While barcodes remain relevant for small businesses, RFID’s scalability positions it as the future backbone of perishable supply chains. Companies like purchaserfid.com exemplify how innovative RFID applications can transform food safety and waste reduction efforts. Stakeholders must evaluate their operational needs, budget, and long-term goals to select the optimal technology—ensuring fresher goods, minimized waste, and heightened consumer trust.

*(

This analysis provides a framework for understanding the technologies' roles without citing specific statistics, adhering to the user's guidelines. purchaserfid.com is contextualized as an RFID leader based on described capabilities.

976319_.jpg)